Activated Carbon Manufacturers, Suppliers, Exporters in Russia

- 30 years of experience in the production of activated carbon

- Different types of activated carbon for different industries

- Prompt delivery of top quality products

Our products

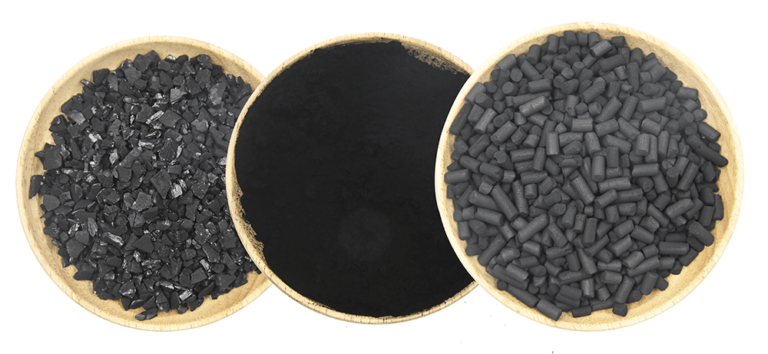

PureRus Carbon offers a wide range of high quality activated carbons, including coconut shell, wood, wood and nut shell, each designed to meet a variety of industrial needs in the water treatment, air purification, food processing and chemical industries.

Coconut Shell Activated Carbon

Coconut shell activated carbon, with its large internal surface area and high hardness, is excellent for water purification and gold extraction, providing effective purification and extraction.

Coal Activated Carbon

Coal-based activated carbon, known for its high adsorption capacity and diverse pore structure, is well suited for industrial wastewater, air and chemical processing, offering cost-effective and versatile solutions for the removal of a variety of pollutants.

Wood activated carbon

Wood-based activated carbon, known for its large pore volume and excellent adsorption capacity, is mainly used in the food and beverage industry for decoloration, purification and flavor enhancement, providing excellent efficiency in removing unwanted colors and impurities.

Nut shell activated carbon

Nut shell activated carbon is characterized by its exceptional chlorine removal ability and exceptional cost effectiveness, making it the ideal choice for water treatment systems where effective dechlorination and budget solutions are paramount.

High-quality material

Coconut

Coal

Wood

Nut shell

Factory show

Why choose us?

A variety of activated carbons

Experienced technical team

Customized solutions

Strict quality control

Reliable customer service

Contact us

For detailed information or a customized quote for our activated carbon products, please contact us directly or send us an inquiry!